Jewelers, both professional and amateur, have used just about every type of metal in existence in their creations. As new alloys and metals are adapted to jewelry making, such as titanium and stainless steel, they are also eagerly embraced and worked into beautiful creations for men and women. While fashion trends using unique and trendy metals come and go, three jewelry metals have stood the test of time and continue to have a strong presence in modern jewelry. They are Gold, Silver, and Platinum.

These three metals and the alloys that utilize them are referred to as the Noble Metals. Noble Metals have four properties in common.

Coveted for its beauty, gold has long captivated the human psyche and is considered the most sensuous metal. Jewelry designers and makers find gold easy to work with and prefer it to other metals because it never tarnishes. Gold is perhaps the most workable metal, which is another reason designers enjoy working with it. A single ounce of gold can be stretched into a thread more than 50 miles long or rolled flat into a sheet that covers 100 square feet in area!

Another reason gold is coveted by both consumers and designers is that it lasts indefinitely, especially if properly cared for. Recent studies show that gold originated in the far reaches of the universe billions of years ago and arrived on earth in its infancy. It does not oxidize or corrode and only a handful of rare acids or hot chlorine bleach can damage gold. Gold can also be reused by melting down old gold objects and reforming the gold into new pieces. For example, old coins and broken pieces of jewelry can be melted down and reused to make a brand new piece of gold jewelry.

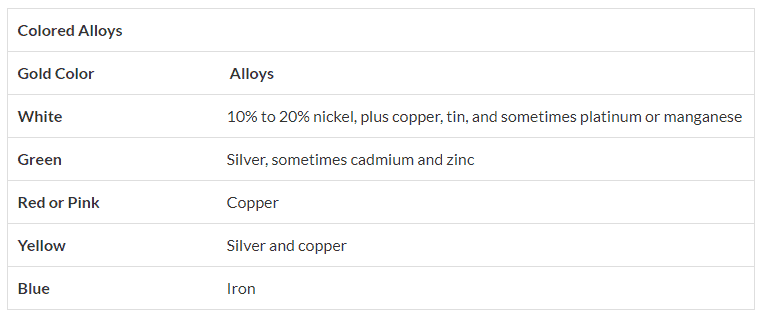

Despite gold’s desirable properties, it does have one significant drawback. It is soft, which means it wears easily. By mixing gold with other metals, or alloying it, gold is made stronger, which makes it durable enough to wear more often without experiencing wear. A variety of metals are commonly used to alloy gold, including silver, copper, nickel, iron, zinc, tin, manganese, cadmium, and titanium. Along with enhancing gold’s strength, alloying gold with other metals changes some of gold’s other properties as well. This is why some gold alloys stain people’s skin or cause an allergic reaction. The reaction is not caused by the gold itself, but by the other metals it is mixed with.

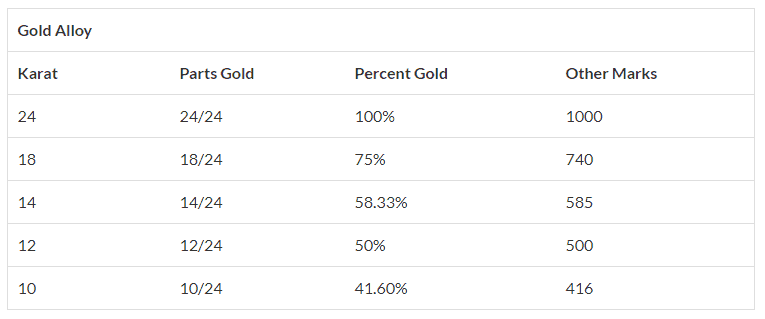

While pure gold is also used in jewelry making, it dents and shows wear easily, which is why most people choose not to wear 100% gold jewelry on a regular basis. When discussing gold and its alloys, the term karat is used to indicate the purity of the gold (Not to be confused with carat, which is a unit of measurement used to describe gemstone weight). Pure gold, which contains no other metals, is termed 24 karat gold. A gold alloy that is 50% gold and 50% other metals is 12 karat gold because it is only half pure gold. Alloys used in jewelry making range from 9 karat gold, which is approximately 37% gold, to 24 karat gold, and are required to be stamped and hallmarked according to purity. A newer alloy becoming popular on the jewelry scene is made of 99% gold and 1% titanium, allowing the alloy to retain nearly all of its gold color while providing improved durability

Mixing gold with different metals changes the color of the gold. For example, mixing copper with gold makes the gold darker yellow, while adding nickel plus zinc or other silver metals produces white gold. Contrary to popular belief, white gold contains no silver, which softens gold and gives it a green tint. Gold alloys also come in colors, including green, red, and blue.

When discussing gold’s purity, or what percentage is pure gold, the laws are fairly strict in the U.S. To be labeled as a specific karat, a gold item must be within three parts per thousand of the karat marking for solid pieces and seven parts per thousand for pieces containing solder. Pieces that fail to meet this criterion must be labeled with a lower karat designation. When labeling jewelry and other gold items for sale, you cannot call an item solid gold unless it truly is 24 karat and if you refer to an item as gold, you must designate what karat the gold is.

The term “new gold” does not mean that the gold was recently mined. It means that the gold has been carefully refined to current gold standards. “Old gold,” on the other hand, comes from melting down old jewelry, coins, and other gold items. This old gold may be a slightly lower karat weight than the original gold depending on how much solder was used in the original jewelry pieces. Impurities in old gold pieces cause a variety of headaches during casting, including bubbles, so old gold is often sent for refinement rather than being melted down by your local jeweler and recast into a new item.

Gold solder, which is used to join pieces together, is actually sold based on its color not its gold content. Because the solder needs to have a lower melting point than the pieces it is joining, it is mixed with metals that have lower melting points than gold. The solder is matched to the gold pieces for an attractive look. Though this poses no problems for the owner of the current jewelry item, melting down this piece with its solder in the future will reduce the karat of the gold.

With solid gold selling for more than $1,250 per ounce (as of September, 2014), many jewelry makers look for alternative ways of giving their customers the look and feel of gold without the hefty price of solid gold. This is often done by coating pieces made from less expensive metals with thin coats of gold. Items that are made this way are referred to as gold overlay pieces.

When shopping for these pieces there are two distinct methods of overlaying the gold that you need to be aware of. The first is gold filled. Pieces that are gold filled have a minimum of 5% gold applied to the base metal. They are classified based on how much gold is overlayed and the karat of the gold. For example, if a piece is marked 1/20 14K G.F., it means that the piece has a 14 karat gold layer that comprises 1/20 of the weight of the piece. The second type of gold overlay, rolled gold plate, is similar, but the gold can be as thin as 1/40 of the weight. It is also stamped by fineness and content, 1/40 14K RGP. Gold platings are the thinner and less expensive of the two types of gold overlays. The gold is a few thousandths of an inch thick, at best, and wear off easily.

The care of gold overlay pieces is quite different from the care of solid gold pieces because of the fact that the gold is layered on top of another metal. As previously mentioned, the gold on these pieces wears off over time and you cannot use a polishing wheel on these items because it will remove the overlay and potentially ruin the item.

With its illustrious history, silver has been more highly valued than gold at various times throughout the years. Long used as a medium of exchange, its name is synonymous with money. Today, silver has found many new uses including photography, batteries, auto glass defogger, and magnetic strips, just to name a few.

Silver’s most outstanding feature is its luster. This Noble Metal is not without its drawbacks though. The main drawback for silver is that it tarnishes. The term tarnish is used to denote a layer of corrosion that forms over some metals, including silver, when they undergo chemical reactions. The chemical reaction that causes silver to tarnish requires a compound called hydrogen sulfide. Silver jewelry encounters hydrogen sulfide in the air you breathe every day, which is why silver tends to tarnish if left out where it is exposed to this compound on a regular basis.

Storing these items in protective pouches or containers where they are exposed to less hydrogen sulfide reduces the amount of tarnish on silver, which means less you can spend less time removing tarnish from your silver jewelry. There are a number of ways to remove tarnish from silver pieces, including silver polish and do-it-yourself methods using common household items, so you do not have to shy away from silver pieces because of the tarnish. Silver jewelry does require more care than some other precious metals, because of the fact that it tarnishes.

Silver is more abundant and much less expensive than gold or platinum, which are additional reasons why it is a popular metal for jewelry; however, it is more difficult to work than gold, because it conducts heat so well. This is why beginning jewelry makers often learn how to solder on silver. Once they gain control of soldering on this highly conductive metal, they find it much easier to control the heat when moving up to gold.

Silver is also commonly alloyed with other metals because, like gold, pure silver is soft and easily damaged. Adding harder metals improves the durability of silver, allowing jewelry designers to design pieces that are beautiful and strong enough to wear every day. The most common silver alloy is sterling silver. Sterling silver is 92.5% silver. The remaining 7.5% is comprised of one or more other metals. A substantial portion of this 7.5% is often copper because it increases the hardness of the sterling silver.

The term Mexican silver applies to silver that is used as currency in Mexico and is typically comprised of 95% silver and 5% copper. While the copper increases its durability, it is used more for currency than jewelry. Typically even the silver jewelry made in Mexico is crafted from sterling silver.

In the U.S., coin silver contains 90% silver and 10% copper. You do not usually see coin silver used in jewelry. Britiannia silver contains a minimum of 95.84% silver, making it a more valuable alloy than sterling. While this may be used in jewelry, it is not common. There are a variety of additional silver alloys used worldwide, including a South American alloy made of 80% silver that does not tarnish. Jewelry makers stamp silver pieces with the code that denotes which alloy of silver it is. For example, 925 is used to designate sterling silver and 958 is used for Britannia silver. When shopping for silver jewelry inspect the piece carefully to determine which alloy was used.

While sterling silver is the most common type of silver used in jewelry making, there are some additional alloys that should be mentioned. Electrum, for example, is a naturally occurring alloy of silver and gold that was popular with the ancient Egyptians. Because electrum occurs naturally in nature, the ration of silver to gold varies with each piece.

Niello is a black mixture of silver, copper, and lead. It is used more like an enamel, so you do not typically see jewelry made entirely of niello. It is used as an inlay on etched or engraved metal or to fill in designs. Like electrum, niello was popular with the Egyptians, who used the mixture during the Iron Age.

While all of these silver alloys actually contain at least some silver, some metal names can mislead you into thinking the metal contains silver. Nickel silver or German silver, for example, are alloys of nickel, zinc, and other metals. These metals look like silver, hence the name, but they do not actually contain any silver. The same is true of quicksilver, which is the ancient term given to mercury due to its appearance. While mercury does resemble liquid silver, it does not contain silver and is not seen in jewelry because it is harmful to your health.

Platinum is the rarest and most expensive of the Noble Metals. Its unsurpassed holding power and durability make it a highly coveted, premium jewelry metal. Platinum is incredibly durable and does not tarnish, which is why it is often used for engagement and wedding rings.

Though platinum has been found in various objects as far back as 700 BC, its use in jewelry is relatively modern. The main reason for this is that refining platinum proved difficult for a number of centuries because the metal has an extremely high melting point and is highly resistant to corrosion. The oldest recorded use of platinum is as an inlay in ancient Egypt. However, the Egyptians though it was a variation of electrum. Native Americans used platinum in small decorative objects for centuries. Platinum was unknown to Europeans until the Spanish settlers discovered it in Columbia. The Spanish called it platina, meaning little silver, and believed it was unripe gold and, therefore, unusable.

It was not until the eighteenth century that platinum was identified as a new metal and a researcher from Sweden figured out how to melt platinum with arsenic. Once individuals learned how to refine platinum they began to use it to decorate porcelain and to make laboratory equipment. The use of arsenic to refine platinum was extremely dangerous, which is why platinum did not gain popularity until the oxyhydrogen torch was invented in the mid 1800s.

Discoveries of platinum ore in several countries in the nineteenth century brought platinum to the attention of jewelry makers and platinum quickly became a symbol of wealth and celebrity status in the early 1900s. Stars like Greta Garbo and Cole Porter frequently appeared on film with platinum jewelry and accessories. It also became popular for setting exceptional gems. For example, the 530-carat “Star of Africa” diamond in the British royal scepter is set in platinum.

While platinum is still highly coveted in the jewelry industry, it is also used for a variety of industrial purposes. Today, platinum is commonly found in catalytic converters because of its ability to cause chemical reactions while remaining unchanged. In fact, half of the platinum mined in the U.S. and a quarter of the platinum mined worldwide is used for this purpose. The U.S. Bureau of Standards also uses platinum for weights because it never oxidizes and, therefore, remains the same weight forever.

Though most people believe that the term platinum refers to one single type of metal, the truth is it is used to refer to a group of metals that share similar properties. The platinum group includes platinum, iridium, palladium, ruthenium, rhodium, and osmium. Platinum is the most abundant; however, it is not the only one of the group that is used for making jewelry. Rhodium is popular as a non-tarnishing plating for white gold, silver, and other platinum metals. Others from this group, including palladium and iridium, are alloyed with other metals or used alone to make jewelry. In fact, all but osmium are used for jewelry. The most common platinum alloys include 90% platinum and 10% iridium, or 95% platinum and 5% ruthenium. Ruthenium makes for the harder and stronger alloy.

Alloy: Mixing two or more metallic elements, especially to give greater strength or resistance to corrosion

Amalgamation: Purifying gold by mixing it with mercury.

Cementation: To surround a metal with a substance that will react with the metal under heat. Silver is parted from gold by cementation with salt.

Cupellation: A means of separating gold and silver from other metals and impurities. The ore is heated in a cupel, (a ceramic cup,) which absorbs the impurities.

Distillation: Metals with a low boiling point, like mercury, are vaporized to separate them from other metals.

Noble Metals: Metals that resists corrosion and oxidation.

Smelting: To melt an ore to separate and refine the metals within it.

Water Concentration: Washing ore causes the heavier metals to stay behind where they can be recovered.